Menu

Location Find a Store

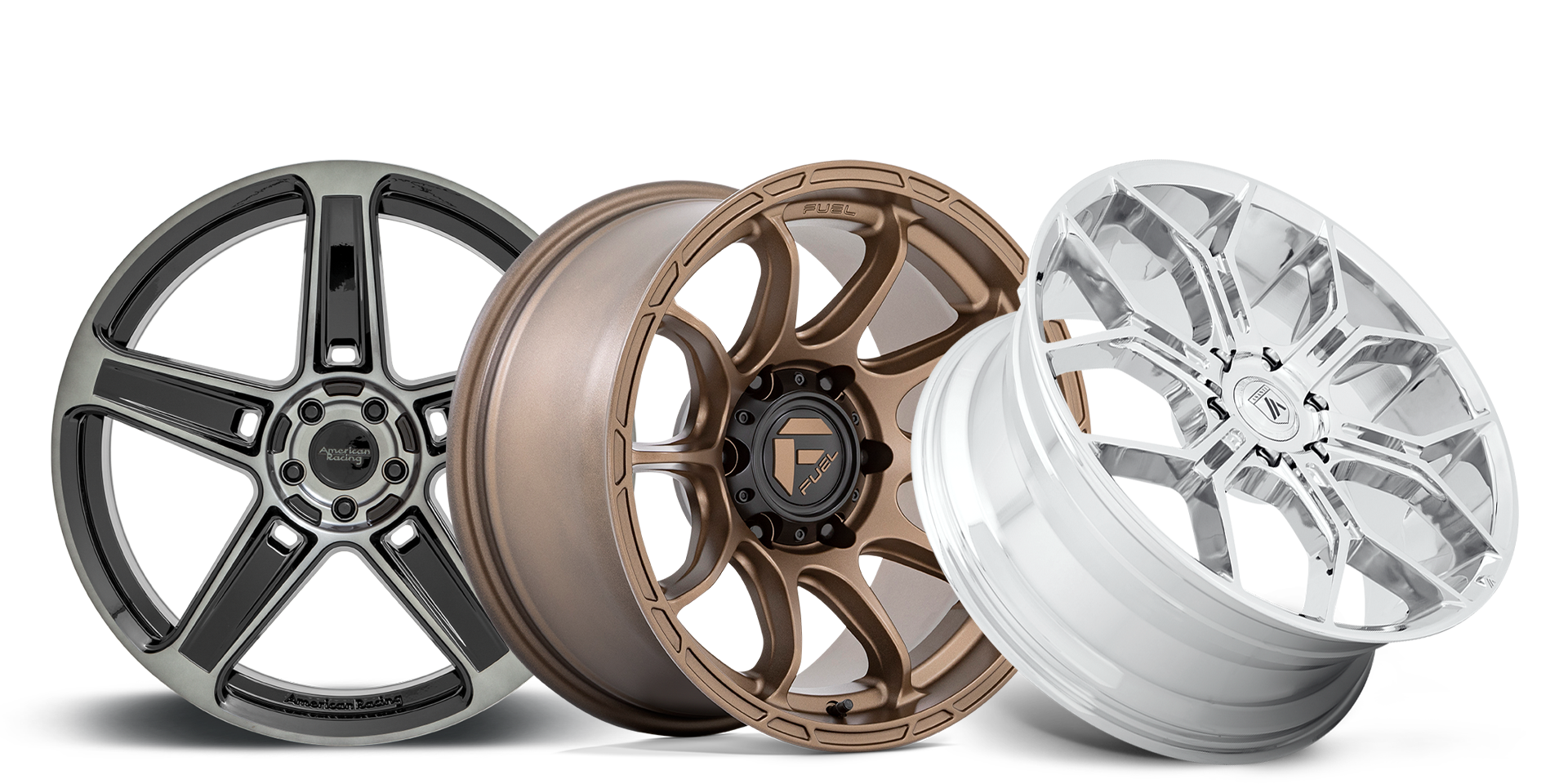

Premium Wheels, Unbelievable Deals.

Huge selection of top-tier wheels and tires at unbeatable prices.

Experience our hassle-free, no-credit payment program today.

Why RimTyme Experience the Difference

More Wheels

We carry a large selection of name brand custom wheels and tires to fit any vehicle.

Real Experts

Our staff are automotive stylists that know the latest trends and styles, so we can give our customers the custom wheels and tires they want.

Easy Options

Our payment options, give you the flexibility to make payments: weekly, bi-weekly, monthly or buy your wheels today at our everyday low prices.

Payment Options Getting started is easy

No credit needed

No credit. No problem! We offer a variety of payment options to fit everyone's budget.

Flexible payment options

Our options will have you riding today with minimal out of pocket expenses and with as little as $50 down.

Get pre-approved today

Start now by selecting a set of custom wheels and tires with the right payment option that fits your budget.

NEED SHOPPING ASSISTANCE?

Can't find what you're looking for? Want to talk to someone about our flexible payment options?

About Us RimTyme Custom Wheels and Tires

We carry the largest in-stock selection of chrome, black and machined, polished and painted wheels to give your vehicle that custom look you want. Our wheel experts can assist you in selecting the right rims whether you are shopping for your street or off- vehicle, wheels for your Jeep, car or truck. We take pride in offering popular name brand wheels in the latest styles, finishes and sizes. Roll today with flexible payment options, choose cash, credit, or our unique payment program on your next custom wheel and tire package. Check out our additional rim and tire options when you shop us at rimtyme.com.

RimTyme | Treat Yourself